Design Synergy

Phone: +44 (0) 1536 516 053

Copyright © 2014 Design Synergy Ltd, 22 Hall Lane, Kettering, Northants NN15 7LJ

Machine Vision, Cognex Cameras, Automation Design, Machine Design, Special Purpose Machinery, Bespoke Machines, based in Northamptonshire and covering the Midlands, East Anglia and all of the UK

Vision and Automation Specialists

Machine Vision, Cognex Cameras, Automation Design, Machine Design, Special Purpose Machinery, Bespoke Machines for the Midlands, East Anglia and all of the UK

Case Studies

Inspection and

Tracking System

Food products are inspected as they progress along a conveyor at high speed. A high speed Cognex camera identifies any defects and these are tracked down the conveyor and rejected. The conveyor speed is high and therefore the reject mechanism has to be selective and fast. A second colour camera identifies colour defects which are similarly rejected.

Inspection System

Centrifuge

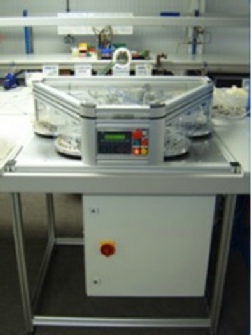

This was designed and manufactured for a research organisation as part of their test regime. It is driven by an AC motor controlled by a Mitsubishi inverter and PLC. A small display gives the operator up to date operational conditions.

Assembly System

This is a complex assembly system for high integrity components. In order to achieve a cost effective solution it was decided that this machine should use the dexterity of an operator to load the machine rather than the cost of full automation using bowl and linear feeders. This resulted in a compact design fitting into an existing workspace at a realistic price.

Assembly System

Centrifuge

Inspection System

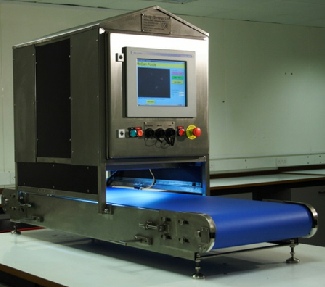

This machine is designed to measure and inspect raw food stuff which is manually loaded onto the rear end of the conveyor belt. Statistical results are reported on the touch screen PC after a batch has been analysed. A colour Cognex camera is used to make measurements and analyse colour content. A connection to the factory LAN allows images and results to be viewed anywhere in the factory.

Inspection and Tracking System

Robot Application

A Kawasaki robot was adapted for use within a University environment. It has a number of interchangeable heads which are used for research work on composite fabrics.

Robot Application